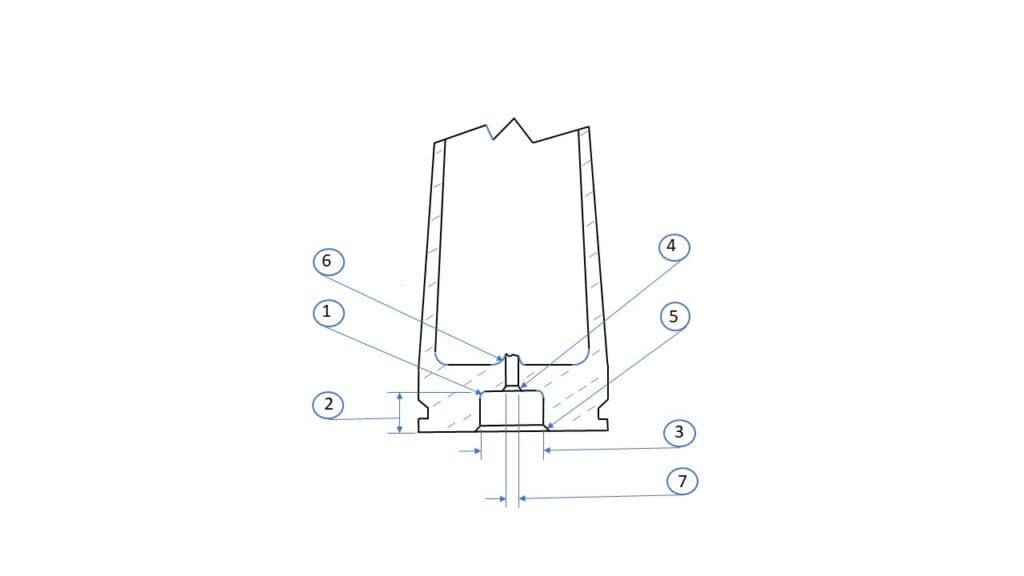

Shooters reloading ammunition for bench rest, varmint, class F, or any long-range rifle sport will do well to correct brass case variations. Here we are looking at the primer pocket. Additional articles will follow detailing improvements to other areas of your brass for optimum accuracy. Refer to the bottom of this article for drawing numbered items.

- A small radius in the very bottom corner of the pocket is almost always present, what’s to do here you may ask. If you examine a boxer primer closely, you’ll see the anvil is not seated flush into the cup. This is not a manufacturing error; it is purposely made this way. The manufacturer intends the user to push the anvil in all the way when seating the primer into the pocket. Seating the anvil makes the priming compound more sensitive. What does the radius at #1 in the drawing have to do with it anyway? The brass radius will limit the amount the anvil is seated, variations here can cause slightly irregular ignition. To get everything as uniform as possible we want to remove the radius, once done, all primers will be seated to the bottom of the pocket with the anvil properly seated. Several tools are made to true up the primer pocket. One source is Brownells Inc. they normally stock about 4 different brands. These primer pocket uniformers are available for large and small primer pockets. If you buy a carbide cutter you will probably never wear it out in a lifetime of use. In use If you turn the cutter with a low RPM drill or any powered driver you won’t need a handle, saving a lot of hand fatigue.

- 2. Looking at this area, the depth of the pocket will be uniformed in step 1. A cutter having a shoulder will provide a stop when contacting the outside base of the case limits cutting depth. If the bottom of a primer pocket is not touched and trued up it would be best to set that case aside for fouling or sighter shots. Several brands of cutters have an adjustable stop collar. In personal experience the Sinclair carbide cutter, with a fixed shoulder, from Brownells is superb, it can’t get out of adjustment and is of top quality.

- 3. Now we come to the inside diameter of the pocket and again primer pocket uniformers performs this in step 1. Terrific, we have now performed three improvements in one operation.

- 4. The flash hole in this area will vary slightly from case to case, and may have a burr present. Most brass manufacturers use a punch press to make the hole. It has been stated Lapua drills it, this may still leave a burr. The burr is easily removed with a small drill bit larger than the hole with just a very few turns. This is easily accomplished by hand turning the bit using a pin chuck to producing a minute bevel! The drawing shows an exaggerated amount of deburring.

- 5. Now a look at the exterior of the primer pocket circumference, again we just want to debur it. This is easily accomplished with a case mouth neck cutter normally used after case trimming. It works great in this area, only a few turns by hand are enough to cut a very slight bevel. This makes priming smooth helping prevent deformed primer cups. Again, the drawing shows an exaggerated amount of deburring.

- 6. Normally there is a substantial burr inside the case at this location. Here the drawing shows the burr before deburring. Numerous tools are available designed to remove this burr. It is important to not cut this too deep compromising the integrity and strength of the case. Several tools made for this operation have a stop collar to limit the cutting depth. If the tool has an adjustable stop collar all cases should be trimmed to an exact uniform length before this tool is used. Use caution just debur and possibly a few thousandths deeper to form a minute bevel.

- 7. Some tools used in step 6 above will also uniform the diameter of the flash hole. If all flash holes are the same diameter, they will allow the primer ignition flame into the powder charge equal shot to shot. Again, we are looking for uniformity throughout. Please note there was a design change made to military 5.56 X 45 brass not many years ago. You will find the newer brass to have the same diameter as large primer pocket flash holes. Earlier 5.56 X 45 military brass will have smaller flash holes.

Hopefully this information will prove helpful in performing cartridge case uniformity, once accomplished these steps will not have to be repeated on a given case.

If you have any questions, call us, 479-629-5566, 9am to 9pm central time Mon-Sat. If the line is busy leave a message we will call back. Thanks very much for considering our firm for your cartridge case neck annealing needs. If you have any questions, call us, 479-629-5566, 9am to 9pm central time Mon-Sat. If the line is busy leave a message we will call back. Thanks very much for considering our firm for your cartridge case neck annealing needs.

Tom Wilson Fort Smith, AR 9-21-23©