Learn the complete brass annealing guide with our detailed table. Find out how to optimize your reloading process, increase the life of your brass, and achieve consistent shooting results. Don't miss the opportunity to master the art of brass annealing!

So, you’ve been reloading for a while and have a good supply of brass. Now, after 5 to 7 firings, you’re seeing brass necks cracking. Premium quality rifle brass is expensive. 338 Lapua is over $3.00 ea. .308 Win. $1.00 + ea. & some cases very difficult to fine.

You want to extend your brass life and have heard of case neck annealing. A knowledgeable reloader may have advised that he anneals case necks, which extends brass life and improves accuracy. This fellow may have cautioned regarding the hazard of annealing the case head, (the base) as this may cause a rupture to blow out when fired. This can wreck the firearm, possibly injuring the shooter. After hearing this, you may have put the idea of annealing case necks out of mind for a while. As time has progressed, you may have scrapped your original supply of cases and are again experiencing failure from cracked necks. When a case is fired and reloaded, the neck is moved 3 or 4 times. This results in work hardening. The only cure is neck annealing.

A bench rest shooter, who anneals his brass after every firing, set an outstanding record with a group less than 1″ at 600 yards. The 6 BR brass he used for this record was fired for the 58th time. Bench rest guns normally have tight chambers. This represents a dramatic extension of brass life, as well as superb accuracy. By now you may have decided it would be good to at least investigate case neck annealing.

Many years ago, this reloader attempted annealing some .30-06 brass with poor results. At that time, information was almost nil. The instructions were to stand the cases up in a pan, add water to 1/3 case length. This way, the case head could not be heated above 212 º F. (bass begins to anneal at 482 º F.). The instructions were to heat each case neck with a torch to a low red glow evenly all of the way around and then tip it over into the water. No mention was made as to the proper temperature the case neck needed or what might happen if it was overheated. With this information, annealing was performed with the cases standing in a shallow bath of water. A propane torch flame was applied to the case necks. There was no method to measure neck temperature and a number of these cases were overheated. After all, if a low red glow is good, then heating to bright red had to be better. This seemed like good logic at the time, sadly this was totally wrong! By the way, at what temperature is brass at a low red glow anyway? Years later, it was determined a low red glow, even in dim lighting, is too hot. All of the cases on hand were annealed in the above manner to a very good red glow. When these cases were just neck sized in the next reloading many failed with collapsed shoulders. The neck and the top of the shoulders were too soft resulting in scrap brass. At this time, cartridge case neck annealing was abandoned.

Years later, the sport of high-powered offhand rifle silhouette shooting was of interest and a quantity of 7.62 X 51 brass was needed. A good supply of once fired military brass was obtained. Some was match brass fired in rifles, others from machine guns, which have generous chamber dimensions. It was determined the entire lot of about 1,000 pieces should have the necks annealed.

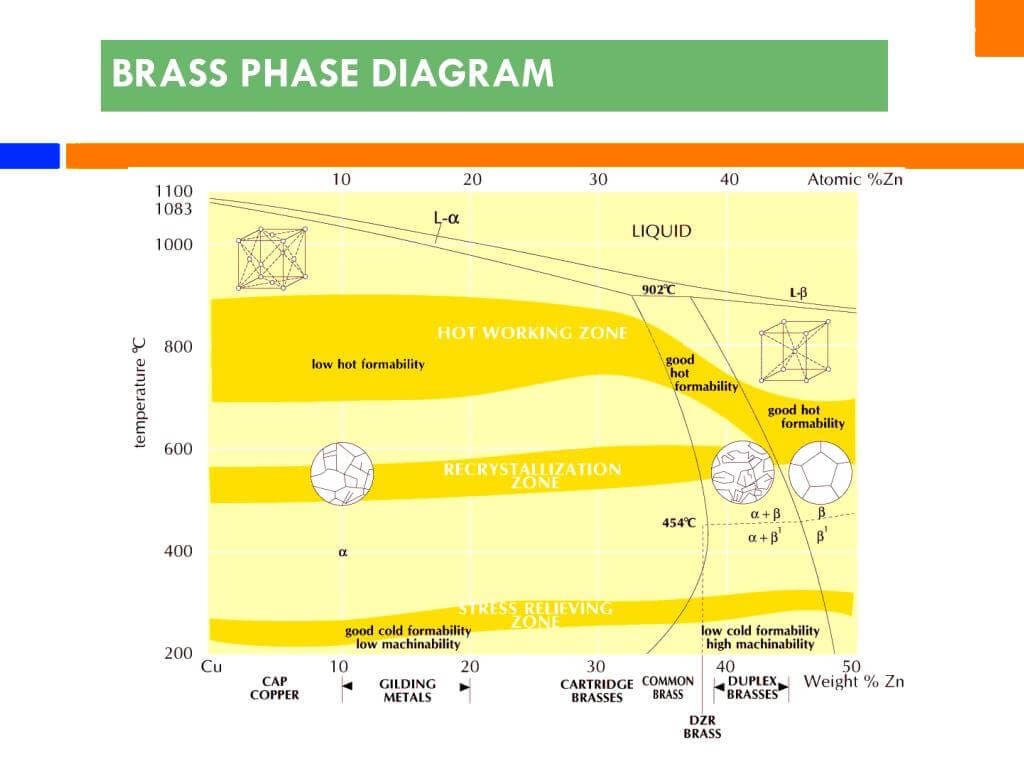

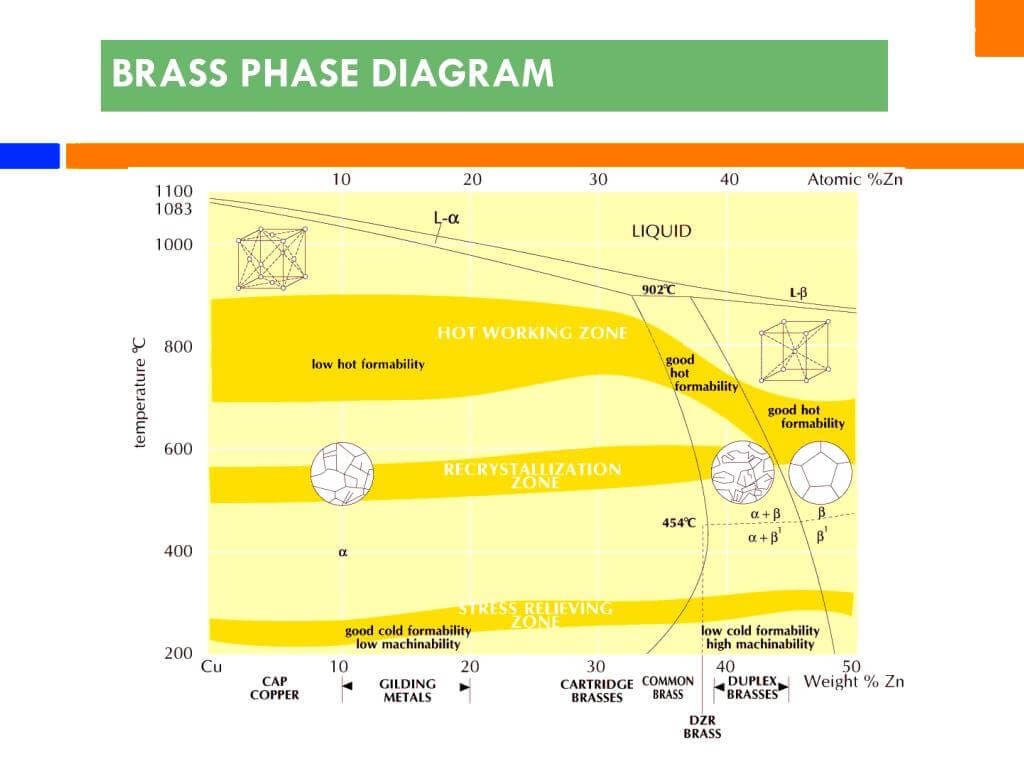

Research began to obtain precise cartridge brass neck annealing information. It was soon found that cartridge case necks do not have to be quenched in water after they are heated. The water bath only assures case head annealing cannot occur. Metallurgists advise water quenching has no significant effect when annealing cartridge brass necks. Cartridge brass is 70% copper and 30% zinc. An ammunition manufacturer stated 700 º F. being the low limit and 800º F. the max. temperature for neck annealing. The case should be quickly brought within that range then air-cooled resulting in proper case neck annealing.

With this information, the target neck temperature was set at 750 º F. Also, the case head had to be kept under 482º F. to avoid annealing it. These were now the parameters to successfully anneal the case necks.

An infra-red heat measuring gun was investigated to determine temperature. The manufacturers advised to obtain accurate results all brass had to have the same reflective finish with the infra-red gun calibrated to that finish. This would be doable as most serious reloaders clean their brass anyway, only requiring inspection for a uniform finish. The manufacturer of the infra-red heat gun then stated it would not read the brass temperature correctly if the beam was directed through a flame, so the heat gun was abandoned. Brass neck annealing occurs rapidly; the necks would be in the annealing flames for only a couple of seconds. Temperature readings had to be instant and accurate. 750º F. Tempilaq® solved this problem.

There are cartridge brass annealing machines on the market, costing from about $300.00 to over $1,400.00. As a cartridge brass annealer only performs one step in reloading it didn’t seem cost effective to invest that much in a tool performing one operation.

A new design was begun; it would have to be efficient, practical, and affordable. The resulting annealer is a rig that easily positioned a case neck between 2 opposing flames for quick annealing and allowed quick removal when annealing occurred. A prototype was built using a 1″ square aluminum block 4″ long having a hole bored in each end larger than the outside diameter of the cartridge case head. This design allows a case to slide in and out easily. A hole was cross-drilled in the center of the 4″ aluminum bar for an axle. This aluminum bar is designated as the cartridge case holder. A wooden knob was installed to turn the cartridge case holder by hand as it gets hot, acting as a heat sink on the case. This helps prevent case head annealing. In use, a case is inserted clear of the flames, then rotated into and between the two flames which impinging on and wrapping around the case neck, heating it uniformly. The prototype worked perfectly; this product is now available as the Anneal-Rite. A variety of cartridge case holders are available ranging from 9mm pistols to the largest for .50 BMG. The entire unit, with one common-size cartridge case holder starts at a little over a hundred dollars delivered, including a bottle of 750º F. Tempilaq® heat indicating fluid, it’s guaranteed accurate to +-7 1/2 º F. Annealed cases are processed at 500 to 600 per hour. The Anneal-Rite comes with a money-back guarantee, assuring perfectly annealed case necks. A demo video can be viewed at www.cartridgeanneal.com. Customer service is available at 479-629-5566. You will get a person on the line from 9am to 9pm Monday through Saturday. You do not have to suffer with premature case failure or spend three to fourteen hundred dollars. This reloader got a 5 shot .620″ group at 300 yards using the neck annealed 7.62 X 51 military cases mentioned.

Tom Wilson ©

You may have considered annealing brass case necks, but were hesitant. Viewing some YouTube annealing videos you concluded guessing brass temperature by color being a wild guess, potentially dangerous, and you would be absolutely correct. Without annealing, brass usually begins failing after 5 to 7 firings, with cracked necks. A bench rest shooter set a 5 shot .861” group record at 600 yards a number of years back. He stated he anneals after every firing, it was the 58th time he fired this brass (tight custom chamber). It’s well-documented correct brass case neck annealing increases accuracy and lengthens case life. The Anneal-Rite guarantees perfect results every time, annealing 500 to 600 cases per hour. This is twice as fast as the induction unit and at a fraction of its cost

Correct cartridge case neck annealing is incredibly beneficial, increasing the life of your brass and tightening your groups. However, if annealing isn’t done properly, not only are these benefits nullified, but the resulting brass can be dangerous. With proper annealing, which is guaranteed with the Anneal-Rite, you always get precise results.

NO – ABSOLUTELY NOT! An annealed case head can blow out when fired, wrecking the firearm causing bodily injury. The key to proper annealing is heating the case neck evenly & quickly to 750° F. then letting it air cool. This must be done without increasing the temperature in the case head (or base) above 481° F. (brass begins to anneal at 482°F). Cartridge brass manufacturers and metallurgists state the proper neck annealing temperature is between 700 to 800° F. Most annealing machines don’t guarantee accuracy, relying on guesswork, or mailing off samples of your brass for analysis. The Anneal-Rite is provided with 750° F. Tempilaq which precisely indicating this temperature totally eliminating guesswork, Tempilaq is guaranteed accurate to plus or minus 7 ½° guaranteeing perfect neck annealing every time.

In the past information on cartridge brass neck annealing was almost nonexistent. The old timers stood cases up in a pan w/water 1/3 case depth. Next, they heated the neck of a case with a torch until it emitted a low red glow, then tipped it over in the water.

The question is what temperature is brass when it emits a low red glow anyway? This method is messy, slow and just a wild guess at temperature. Water quenching brass makes no metallurgical change at all, brass does not react like heat treating steel which hardens when quenched. The idea of water quenching brass was to stop the annealing process and it will stop heating when removed from the heat. Brass manufacturers don’t water quench annealed cases, they let them air cool.

Another old method was to hold a case in your fingers, dip the neck into molten brass and then remove to cool when your fingers got too hot. Before dipping into the molten lead, it was advised to smoke the necks with carbon in order to prevent soldering lead to the case neck.

The Anneal-Rite unit is far faster and guaranteed to give perfect results

There are several carousel-style annealing machines & a few other designs available. These units are expensive, better than standing cases up in a pan of water & heating the neck one case at a time. Typically, these units are not furnished with any temperature measuring method. The Anneal-Rite is reasonable and comes with precise temperature indicating with 750° F. Tempilaq and its guaranteed accurate to plus or minus 7 1/2° F.

Anneal-Rite, if you want to see a very good video showing precise case neck annealing at exactly 750° F. go to www.cartridgeanneal.com and view the demonstration video or call (479) 629-5566 for a U.S rep.9am to 9pm Mon.-Sat

There are two basic methods which give instant and precise temperature readings when the case is being annealed. The first is an infrared temperature sensor that measures metal temperature even looking through flames & give an accurate reading, sadly this device, set up, costs over $5,000.00. The most practical is 750° F Tempilaq, its very affordable, guaranteed to plus or minus 7 ½° F. which is in the exact center of proper neck annealing temperature of 700 to 800° F.

Sadly no, annealing must be done on a regular basis to keep consistently restore the brass to the proper ductility, removing work hardening stresses. It won’t hurt to anneal, don’t bank on returning them to near new condition. This is why many reloaders anneal after every firing. Brass is getting expensive, particularly for premium varieties.

A bench rest shooter set a 5 shot .861” group record at 600 yards. He anneals after every firing, it was the 58th time he fired this brass. Bench rest rifles normally have a tight chamber reamed to close tolerances particularly in the neck area just a couple of thousandths of an inch larger than the loaded round. My rifle is a Remington 700 with standard cut chamber.

A box of 50 - .308 cases currently in use has just past 20 shots per case. These are annealed after every firing and they are still good, best group 5 shot group ever was just under 5/8” at 300 yards, many groups 1” vertical X 3” horizontal courtesy of mother natures wind.

The Anneal-Rite guarantees perfect results every time, annealing 500 to 600 cases per hour. This is twice as fast as the induction unit and at a fraction of its cost.

Certainly, use the same procedure as non-plated. The plating is very thin just enough to cover the brass. There are many cases where nickel plated brass reloaded several times will have the nickel worn through and brass beginning to show. So just anneal it as any all-brass case.

With testing here, we recommend first removing the spent primers, then annealing. In this manner if the case neck would warp even .001” out of round from the heat it will certainly be returned concentric and true after resizing.

Makes no difference at all. If annealed and then, cleaned the cases will never show patina in the annealed area. If cleaned and then annealed the cases will show the patina as darkened metal, however this takes some time to develop as it is oxidation.

YES, our most popular cartridge case holders #1, 2, & 3 are bundled together two ways. You can order these either with or without propane torches. We also have two bundle deals where you can get every cartridge case holder we make allowing you to anneal almost every cartridge case imageable.

Certainly can, we will make any holder you may need for cases up to .823” diameter. It is best to call us for a custom order 479-629-5566 for a U.S rep. 9am to 9pm Mon.-Sat.

Yes, the Anneal-Rite is shipped to most countries, check with your customs to see if items wanted can be legally imported to your country. First email [email protected] stating the items wanted. You will receive a return email advising which of the 3 boxes; small, medium or large will be required, then proceed as follows.

WORLDWIDE POSTAL SURCHARGE (SMALL, MEDIUM, LARGE PRIORITY MAIL BOX)